Coming from someone that builds them. At least where I live the mechanism is proprietary so it may not exist for every extrusion profile. Plus for big enough doors/windows the hinges to bear the load either don’t exist or get expensive quick.

I’ve got an 80cm door with double pane glass (of course) and metal-pvc construction that does this. It’s pretty heavy, it’d have to be a huge window to be heavier than that.

PVC tends to be lighter than the thermal isolated aluminum we usually use. At least the stuff we have over here. (I work with steel and aluminum though. Never dealt extensively with PVC since it requires specific equipment).

Usually the problematic ones are the long “strip windows” (80cmx3 to 4 m) that some places use especially with argon filled glass panes (thick, layered double panes. With argon filling for emissivity. It may be what you have as well). But for them the style in the picture is usually set aside for a vasistas style closure. Which has an extra support for the panel. Paired with a pull string opening mechanism. I don’t know what’s the generic name.

Those only open via vasistas, you can’t swing around a 4m window lol.

Yeah. Didn’t think too hard about it, the idea for that project was to segment it and use tilt and turn. But in the end it was kept a singular window And wasistas was used with the string mechanism for commodity’s sake.

the change of plans we did made me brain fart… sorry It late over here 😅. still. I’ve made some doors that were too heavy For the tilt and turn hinges we normally use. Mostly due to weird glass pane requirements and sizes. The hinges could most likely handle it. But the specifications said otherwise.

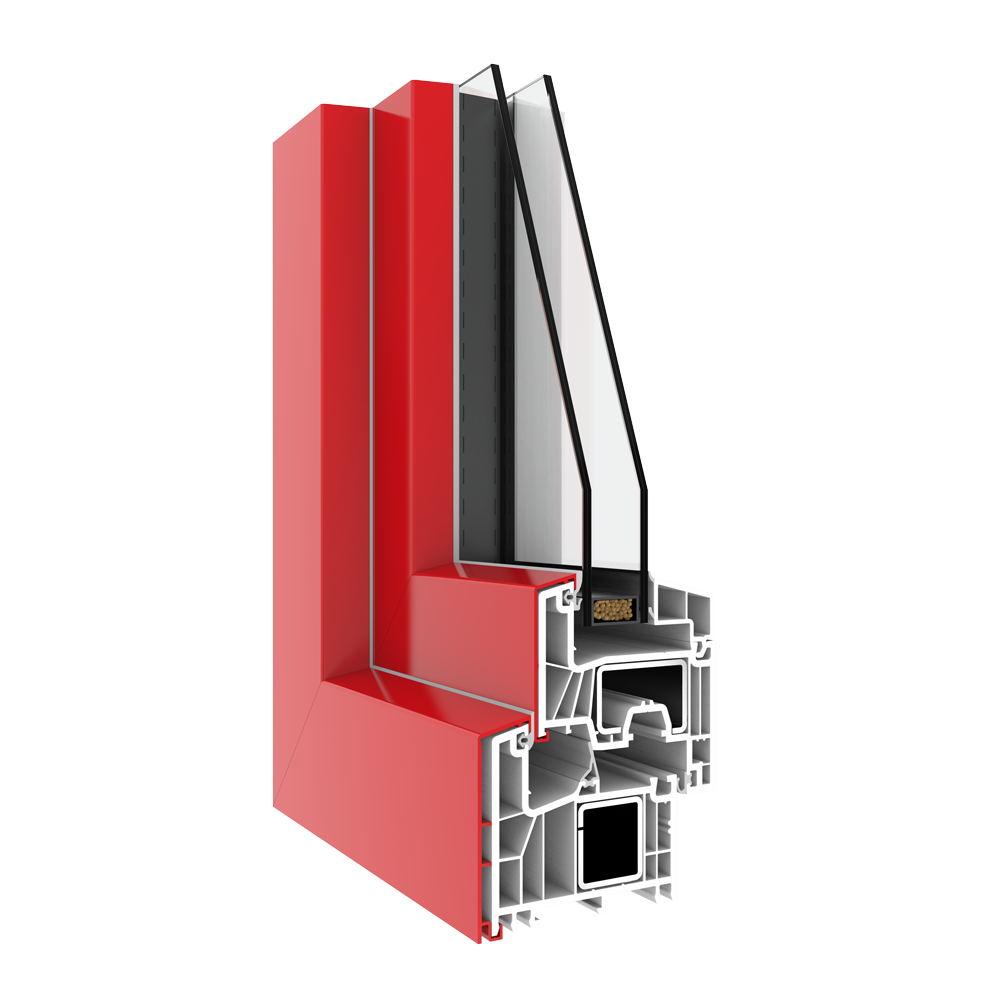

Mine are aluminum frame, steel reinforcements, PVC is only the external layer:

That’s similar to what’s used over here. But iirc the aluminium is not in the ones I’ve seen only PVC and steel Reinforcements. Could be wrong though.

I’m quite sure is the same company though. That profile looks very similar.

Coming from someone that builds them. At least where I live the mechanism is proprietary so it may not exist for every extrusion profile. Plus for big enough doors/windows the hinges to bear the load either don’t exist or get expensive quick.

I’ve got an 80cm door with double pane glass (of course) and metal-pvc construction that does this. It’s pretty heavy, it’d have to be a huge window to be heavier than that.

PVC tends to be lighter than the thermal isolated aluminum we usually use. At least the stuff we have over here. (I work with steel and aluminum though. Never dealt extensively with PVC since it requires specific equipment).

Usually the problematic ones are the long “strip windows” (80cmx3 to 4 m) that some places use especially with argon filled glass panes (thick, layered double panes. With argon filling for emissivity. It may be what you have as well). But for them the style in the picture is usually set aside for a vasistas style closure. Which has an extra support for the panel. Paired with a pull string opening mechanism. I don’t know what’s the generic name.

80x400cm horizontal? Those only open via vasistas, you can’t swing around a 4m window lol. I’ve seen those mostly paired with electrical actuators.

Mine are aluminum frame, steel reinforcements, PVC is only the external layer:

Check it out. Made in Italy.

Yeah. Didn’t think too hard about it, the idea for that project was to segment it and use tilt and turn. But in the end it was kept a singular window And wasistas was used with the string mechanism for commodity’s sake. the change of plans we did made me brain fart… sorry It late over here 😅. still. I’ve made some doors that were too heavy For the tilt and turn hinges we normally use. Mostly due to weird glass pane requirements and sizes. The hinges could most likely handle it. But the specifications said otherwise.

That’s similar to what’s used over here. But iirc the aluminium is not in the ones I’ve seen only PVC and steel Reinforcements. Could be wrong though. I’m quite sure is the same company though. That profile looks very similar.